About

Leading Edge Composites

Who We Are

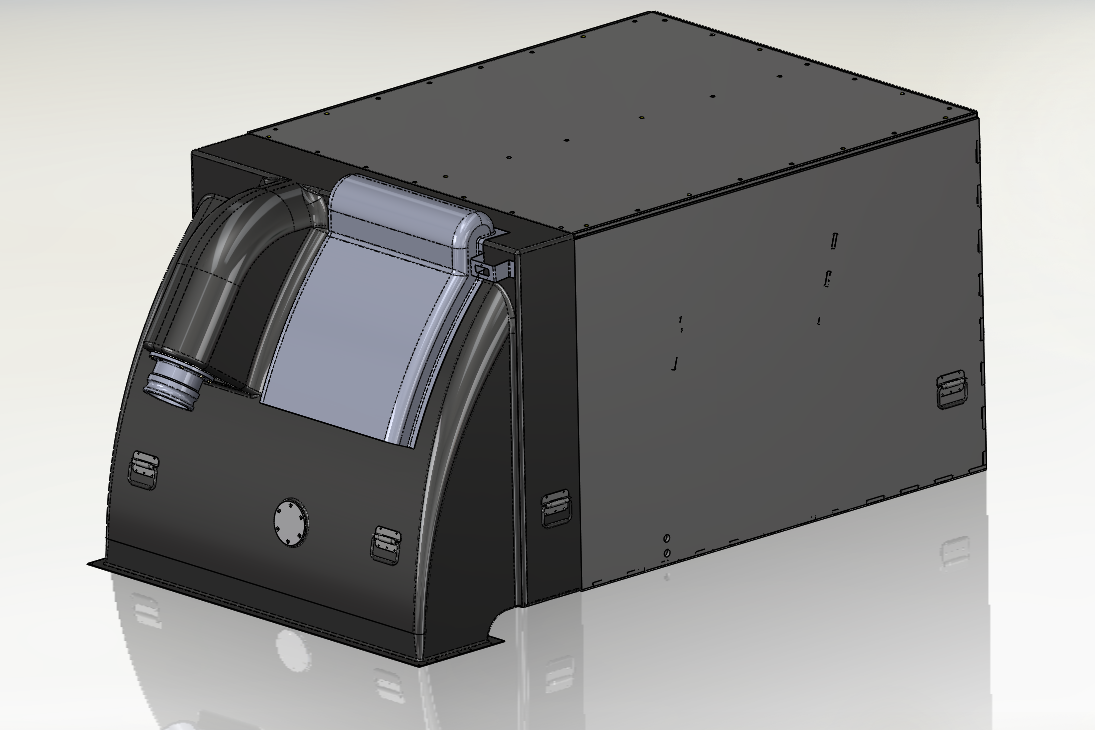

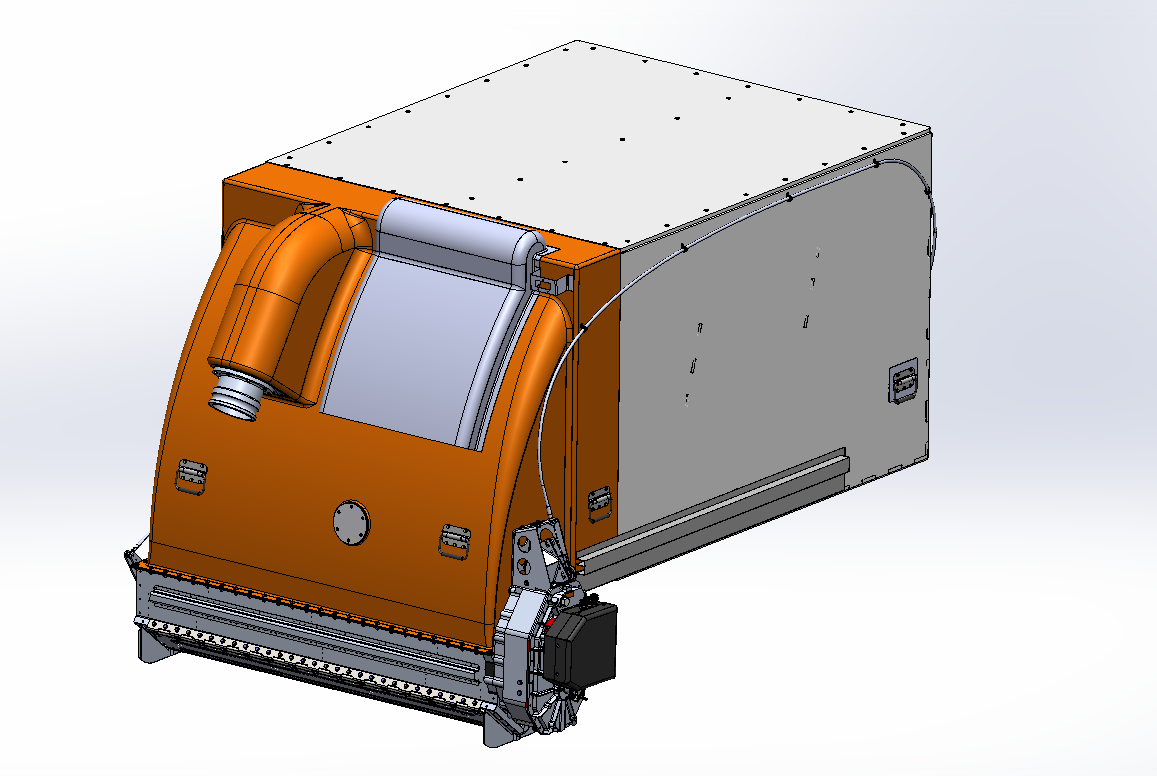

Leading Edge Composites is a full service, fully

integrated design, engineering, and

manufacturing firm specializing in Aviation,

Aerospace, and Defense.

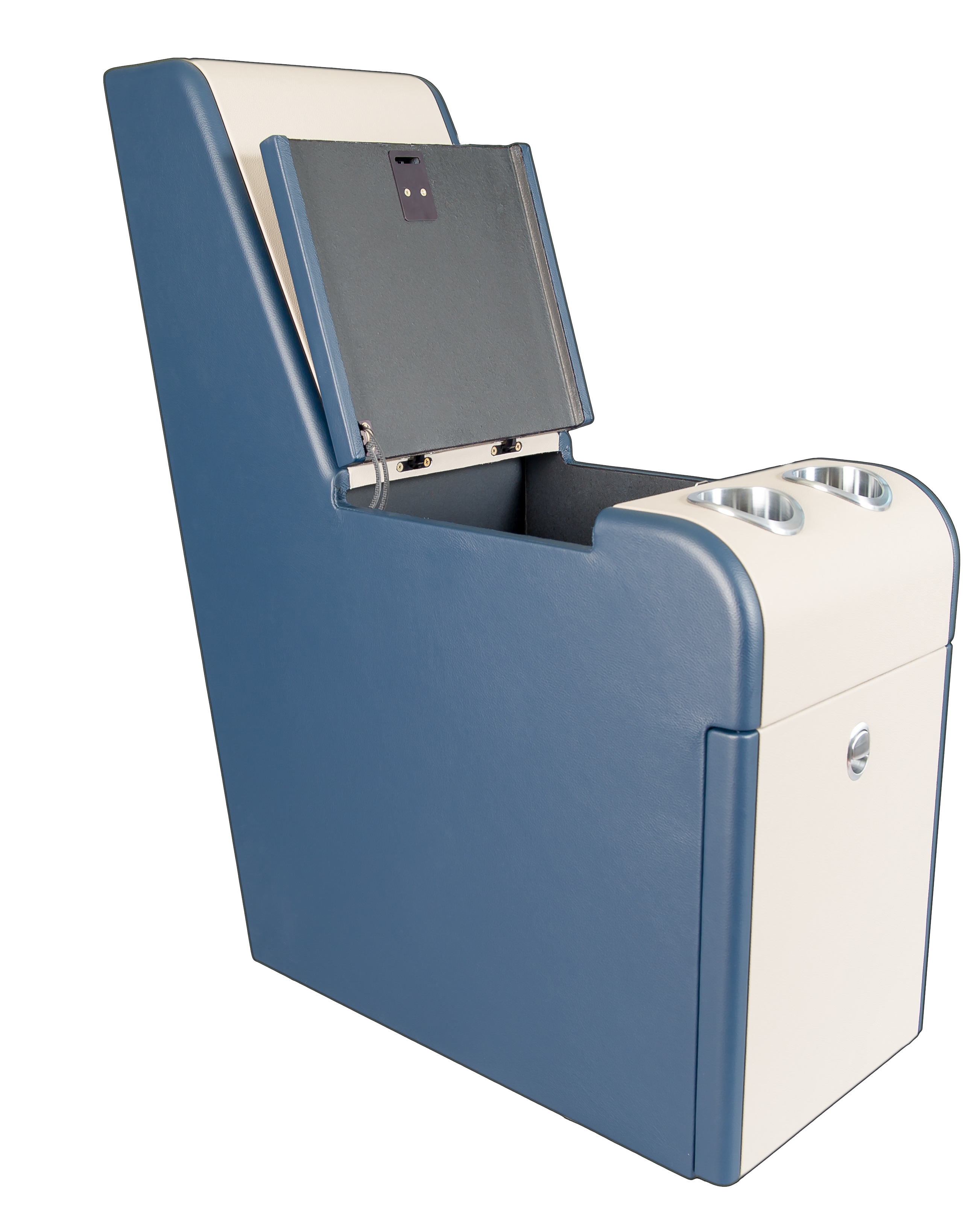

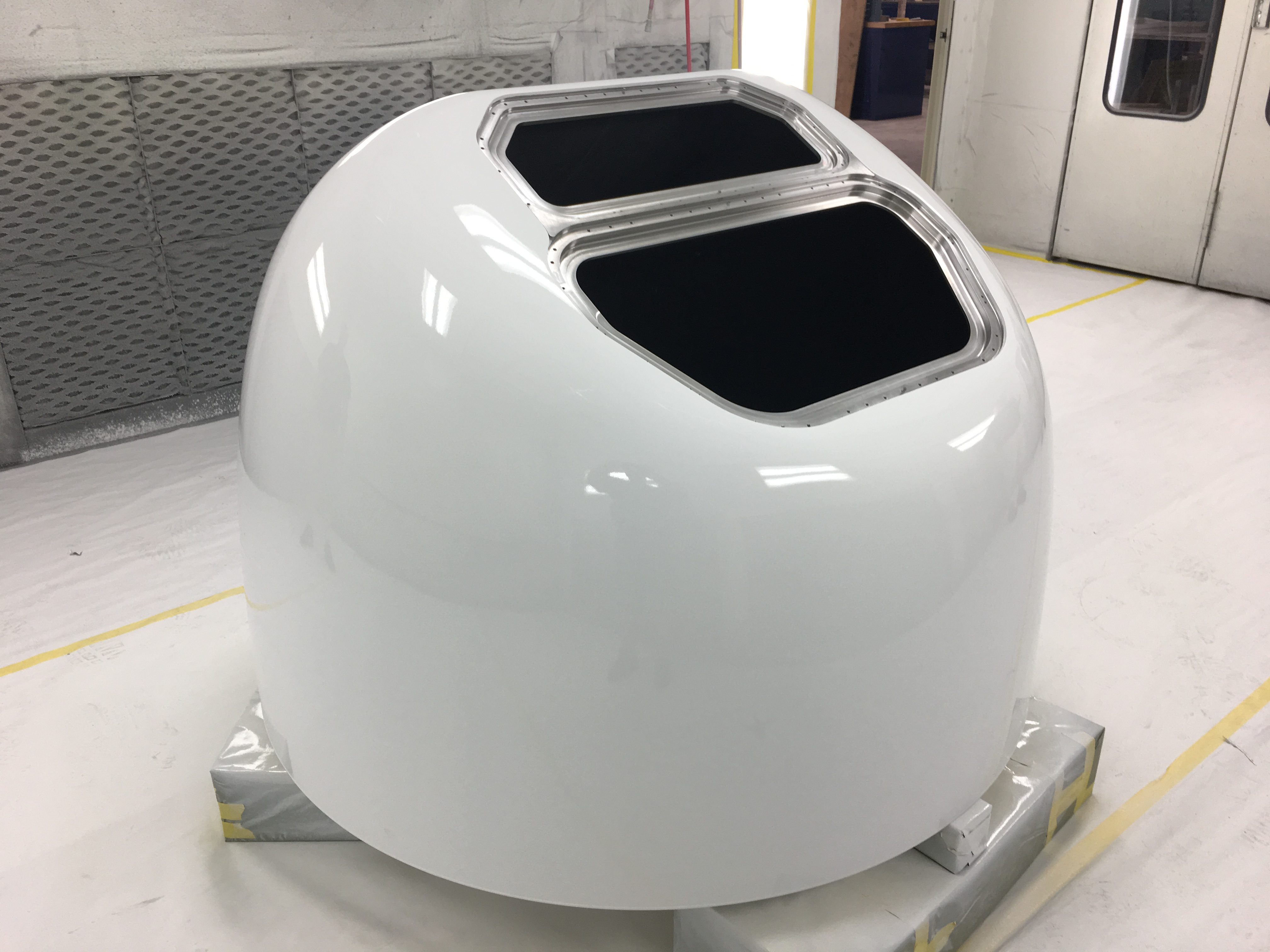

For over 25 years, Leading Edge Composites (LEC) has been at the forefront of composite development and manufacturing, supplying lightweight, state of the art parts for aircraft manufacturers, military research and other structural applications.

LEC has been involved with numerous STCs for upgrading and designing utility, search & rescue and VIP interiors for rotor and fixed-wing aircraft and we have successfully collaborated in the development and manufacturing of aerospace, automotive, military parts, and ballistic panels.

Our Expertise

- Engineering and Design – from concept to final

- Prototyping & Part Development

- Tooling

- Reverse Engineering

- Composite Materials & Processes

- Part Fabrication

- Production Runs

- Assembly

Our Process

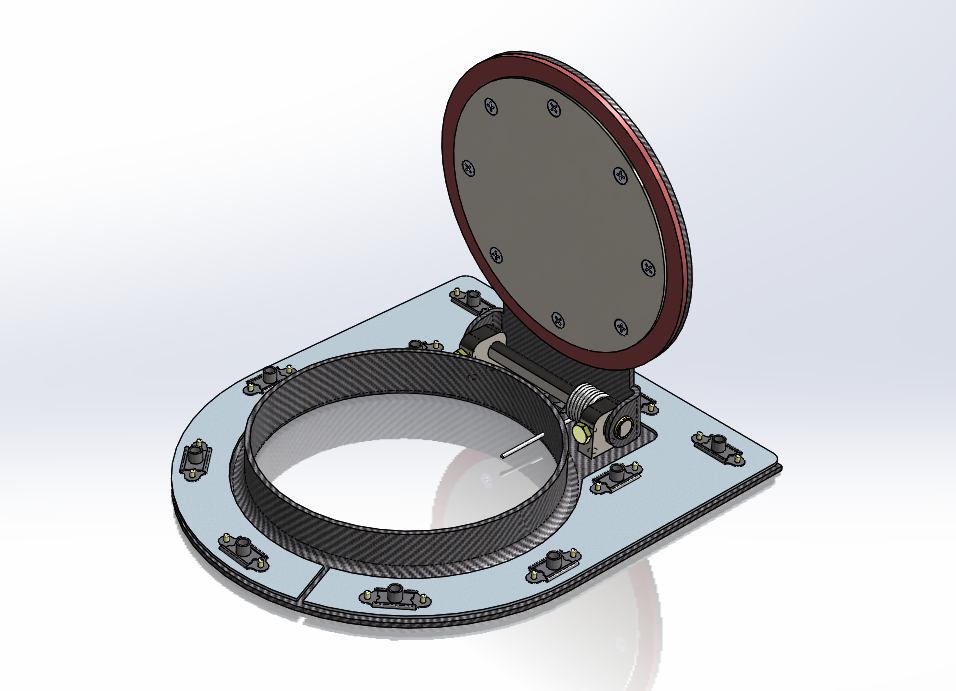

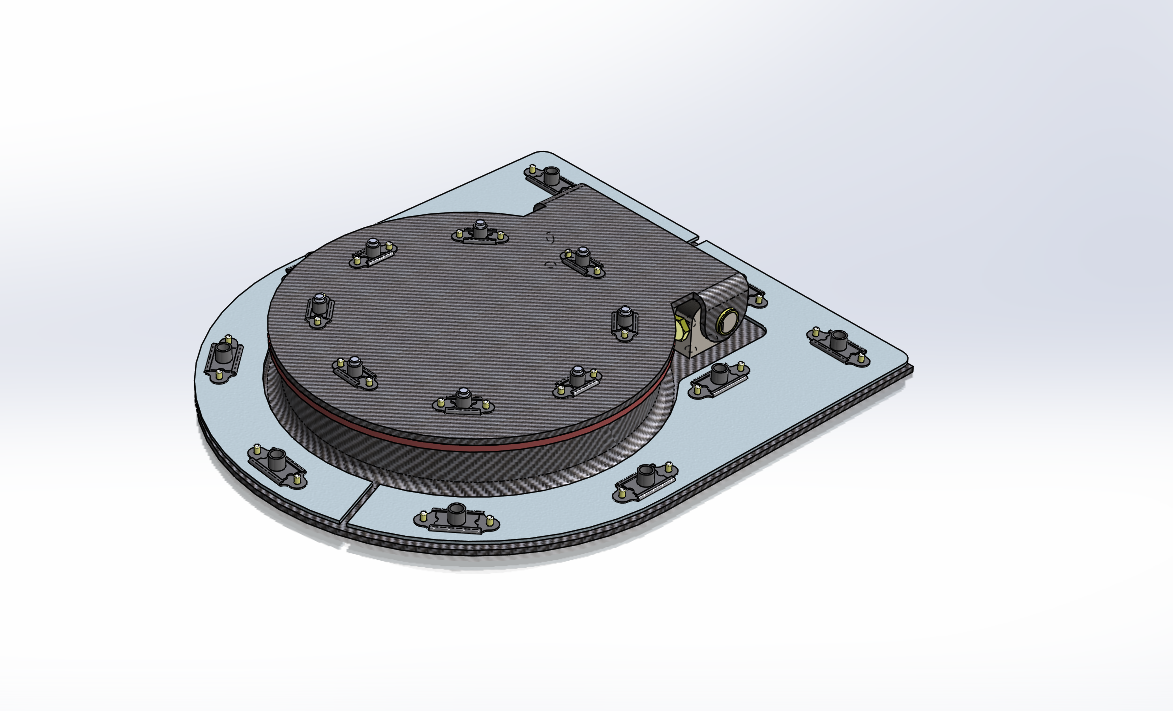

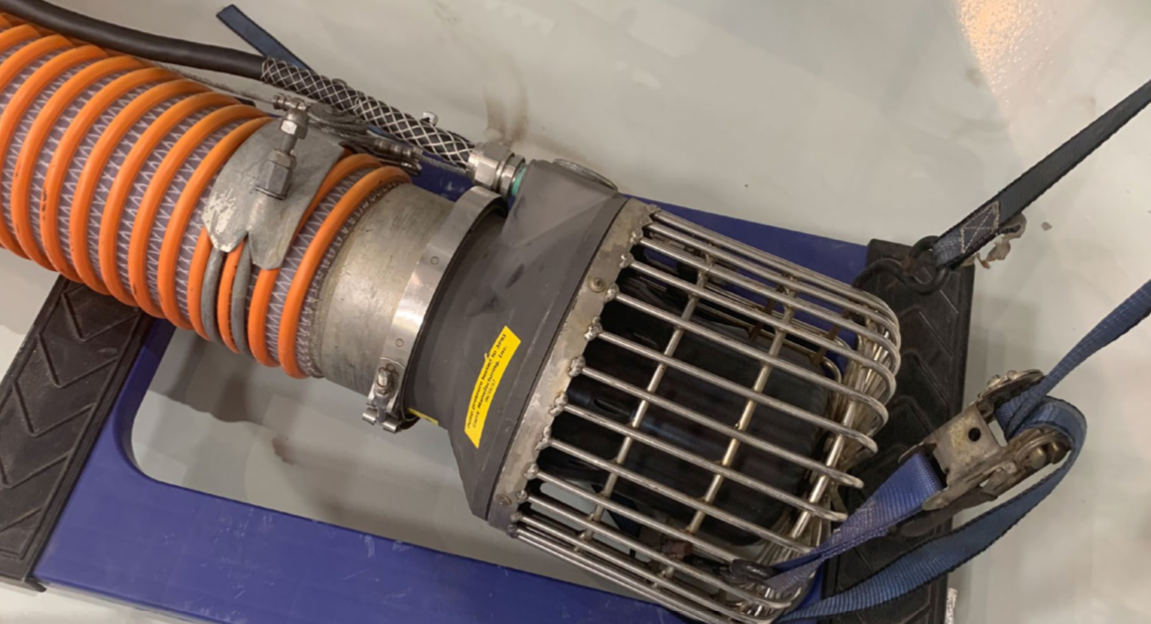

Leading Edge has the in-house capability to manufacture molds and tooling using the highest quality tooling materials and craftsmanship. Our molds and tooling can be designed to handle a wide range of production volumes, dimensional requirements, and processing conditions depending on customer or project requirements. We have the capability to manufacture pre-preg parts utilizing a variety of materials including carbon fiber, Kevlar, and fiberglass with cure temperatures of up to 500° F. Our climate-controlled lay-up/cleanroom is designed to eliminate any possible contamination during fabrication of composite parts, as well as during any modifications or repairs prior to curing.

In addition, Leading Edge Composites has perfected the process of design, layup, and molding of liquid composite parts using VARTM and similar production techniques. These capabilities provide us the opportunity to supply our customers with the most durable, high tech, cost-effective and lightweight composite parts available.

The employees of Leading Edge Composites have been well trained and have extensive experience in the composite industry. Leading Edge Composites is committed to maintaining ongoing education and training of our staff. We attend numerous product and material trade shows to make certain that we are involved with new and upcoming high tech materials, ensuring that we remain at the forefront of the composites industry.

Leading Edge works with the leading Aerospace manufactures such as Sikorsky, L3, Northrop Grumman, Columbia Helicopter, Bell Helicopter, Boeing, Lockheed Martin, Gulfstream, on both civilian and military applications.

Capabilties

Mold, tool and pattern design and fabrication

Fabrication of jig fixtures

5-Axis CNC Mill, 10’ x 10’ x 4’ Envelope

3-Axis (qty 2) CNC Machining Mill, 5’ x 12’ x 1’ Envelope

4-Axis CNC Machining Mill, 5’ x 12’ x 1’ Envelope

3-Axis CNC Bed Machining Mill, 18” x 36” x 18” Envelope

CNC Ply Cutter

FARO Quantum 13’ Portable CMM

FARO Blue HD Laser Scanner

Thermal Curing Ovens 8’ x 25’ x 8’ and 3’ x 3’ x 3’, and Autoclave 6’ x 12’ (Internal) Temperature controlled spray booth

Refrigeration unit for sensitive material storage

Thermoplasic Vacuum Forming

Vacuum Infusion/ (VARTM) & Vacuum Bagging

Prepreg lay-up of Fiberglass, Carbon Fiber & Kevlar

Composite structure repairs and modifications

Facilties and Equipment

Leading Edge Composites has a 40,000 sq ft facility dedicated to composite manufacturing. Leading Edge Composites has the following equipment to perform composite manufacturing of parts: (4) CNC machines, Bel-O-Vac 48”x96’’ thermoplastic vacuum forming machine, wood working machines, sheet metal machines, sheet metal and wood working hand tools, Wisconsin Oven (Cure parts up to 500° F), autoclave access (Cure parts up to 500° F), and a Faro Arm Portable Laser Scanner.

Expertise

Leading Edge currently has 50 full time employees. We are a consortium member with the University of Delaware, Center for Composite Materials, which enables us to access and use their facilities, specialty equipment, libraries, and software.

Certifications and Affilations

NAICS: 336413 | Cage Code: 5SWK2 | JCP: 0073543 |D&B: 037973364 | SIC: 3721 3728 5088 9999 | ISO 9001:2015 & AS 9100:Rev.D Certified | PMA #: PQ2172NE

FAA Certificated Repair Station: 7LER602B

Cabinetry & Interiors

Leading Edge Composites is a full service, fully integrated design, engineering, and manufacturing firm specializing in interior and exterior parts for Aviation, Aerospace

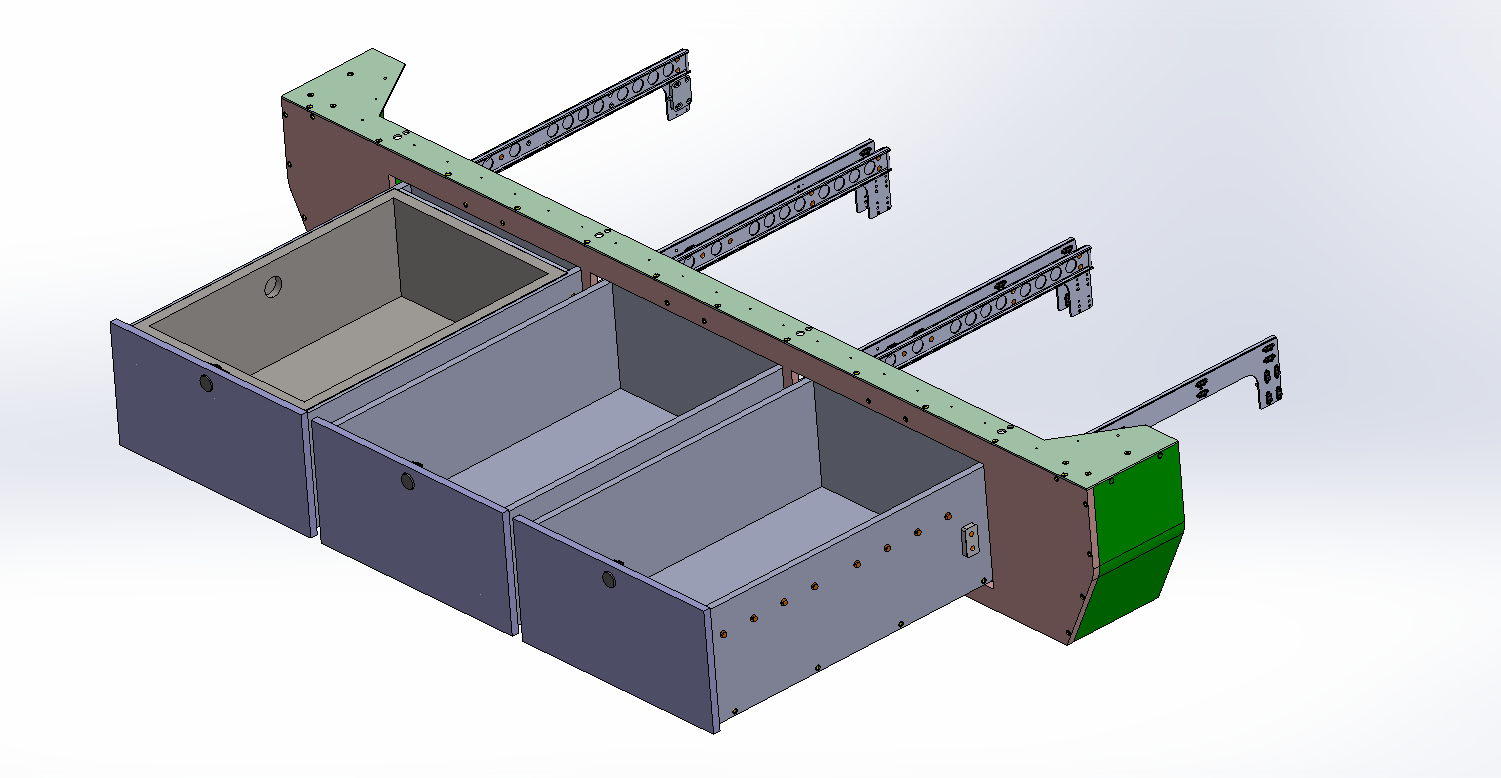

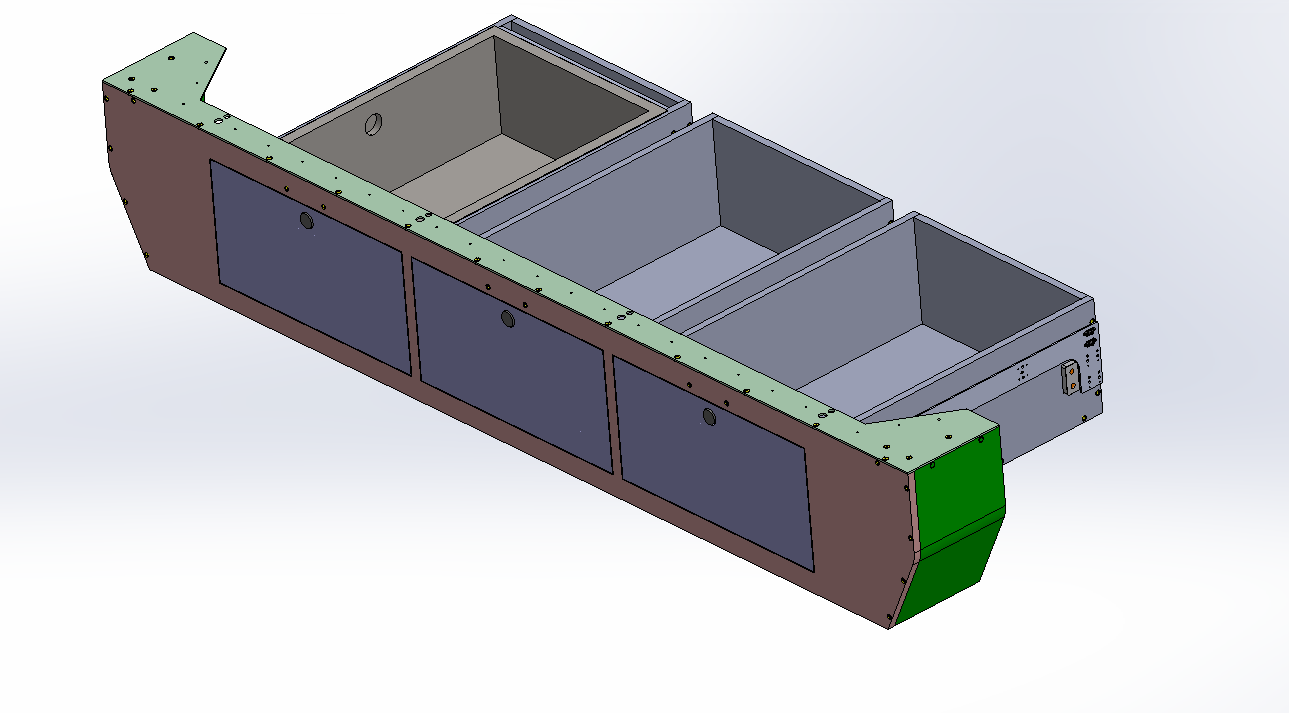

Engineering & Design

- Design of composite laminates and cored structures (honeycomb, balsa, foam, etc.)

- Finite Element Analysis

- PATRAN, NASTRAN

- Design/analysis of complex composite structures

- Composite process modeling

- Composite structure joint design

- CAD/CAM –

SolidWORKS , PRO/Engineer - FiberSIM flat pattern development for complex layups

- Reverse Engineering and inspection of Geometry using portable CMM

Product Development

R&D

- Design for Manufacturing/Concurrent Engineering

- Complete Product and Process Development

- Composite Structure Joint Design

- Adhesive Bonding

- Mechanical Fasteners

- Surface Treatment

- Jig and Fixture Design

- Complete machining capabilities for prototypes, tooling, and production

- Rapid Prototyping – 3D Printing of small parts

Mechanical

Systems

Design

- Specimen preparation

- Adhesive bonding (lap-shear, etc.)

- Strain gage installation

- Precision specimen machining/grinding

- Mechanical Testing

Large variety of ASTM standard testing available- Elevated and low-temperature testing

- Custom test development and fixture design

- Subcomponent, subelement, and full-scale testing of complex structures

Stock Parts & Materials

Take a look at our stock parts and materials. You can purchase the raw materials from us, or we can help you design and customize your parts or prototypes.

Book A Consultation

Contact us to discuss your project or custom design. We look forward to speaking with you.